EXTRA Vol. 152, No. 1

Canada Gazette

Part Ⅱ

OTTAWA, THURSDAY, APRIL 26, 2018

Registration

SOR/2018-66 April 4, 2018

CANADIAN ENVIRONMENTAL PROTECTION ACT, 1999

P.C. 2018-396 April 3, 2018

Whereas, pursuant to subsection 332(1)footnotea of the Canadian Environmental Protection Act, 1999 footnoteb, the Minister of the Environment published in the Canada Gazette, Part I, on May 27, 2017, a copy of the proposed Regulations Respecting Reduction in the Release of Methane and Certain Volatile Organic Compounds (Upstream Oil and Gas Sector), substantially in the annexed form, and persons were given an opportunity to file comments with respect to the proposed Regulations or to file a notice of objection requesting that a board of review be established and stating the reasons for the objection;

Whereas, pursuant to subsection 93(3) of that Act, the National Advisory Committee has been given an opportunity to provide its advice under section 6footnotec of that Act;

And whereas, in accordance with subsection 93(4) of that Act, the Governor in Council is of the opinion that the proposed Regulations do not regulate an aspect of a substance that is regulated by or under any other Act of Parliament in a manner that provides, in the opinion of the Governor in Council, sufficient protection to the environment and human health;

Therefore, Her Excellency the Governor General in Council, on the recommendation of the Minister of the Environment and the Minister of Health, pursuant to subsection 93(1), section 286.1footnoted and subsection 330(3.2)footnotee of the Canadian Environmental Protection Act, 1999 footnoteb, makes the annexed Regulations Respecting Reduction in the Release of Methane and Certain Volatile Organic Compounds (Upstream Oil and Gas Sector).

Regulations Respecting Reduction in the Release of Methane and Certain Volatile Organic Compounds (Upstream Oil and Gas Sector)

Purpose and Overview

Protection of environment and reduction of harmful effects

1 For the purpose of protecting the environment on which life depends and of reducing the immediate or long-term harmful effects of the emission of methane and certain volatile organic compounds on the environment or its biological diversity, these Regulations

- (a) impose certain requirements on the oil and gas sector in order to reduce emissions of methane and certain volatile organic compounds; and

- (b) designate the contravention of certain of its provisions as serious offences by adding them to the schedule to the Regulations Designating Regulatory Provisions for Purposes of Enforcement (Canadian Environmental Protection Act, 1999).

Interpretation

Definitions

2 (1) The following definitions apply in these Regulations.

- authorized official means

- (a) in respect of an operator who is an individual, that individual or another individual who is authorized to act on their behalf;

- (b) in respect of an operator that is a corporation, an officer of the corporation who is authorized to act on its behalf; and

- (c) in respect of an operator that is another entity, an individual who is authorized to act on its behalf. (agent autorisé)

- combustion device means a device in which gaseous fuel is combusted to produce useful heat or energy. (appareil à combustion)

- completion means the process of making a well ready for production, including such a process that involves hydraulic fracturing. (complétion)

- deliver means to transport hydrocarbon gas from an upstream oil and gas facility for a purpose other than to dispose of the gas as waste. (livrer)

- design bleed rate means the rate, expressed in standard m3/h, at which gas is expected, according to the manufacturer of a pneumatic controller, to be continuously emitted from the pneumatic controller while it operates at a given operational setting specified by the manufacturer. (taux de purge nominal)

- destroy means to convert hydrocarbons contained in hydrocarbon gas to carbon dioxide and other molecules for a purpose other than to produce useful heat or energy, and includes the flaring of hydrocarbon gas. (détruire)

- Dominion Lands Survey system means the system for the survey of public lands referred to in sections 54 to 70 of the Dominion Lands Act, chapter 55 of the Revised Statutes of Canada, 1906 that is used in Manitoba, Saskatchewan and Alberta under the name the Dominion Lands Survey system. (système d’arpentage des terres fédérales)

- EPA Method 21 means the method of the Environmental Protection Agency of the United States entitled Method 21 — Determination of Volatile Organic Compound Leaks, set out in Appendix A-7 to Part 60 of Title 40, chapter I of the Code of Federal Regulations of the United States. (méthode 21 de l’EPA)

- equipment component means a component of equipment at an upstream oil and gas facility that comes into contact with hydrocarbons and that has the potential to emit fugitive emissions of hydrocarbon gas. (composant d’équipement)

- flowback means the process of recovering fluids, or fluids mixed with solids, that were injected into a well during hydraulic fracturing in order

- (a) to prepare for further hydraulic fracturing;

- (b) to prepare for cleanup of the well; or

- (c) to initiate or resume production from the well. (reflux)

- fugitive, in relation to emissions of hydrocarbon gas, means the emission of hydrocarbon gas from an upstream oil and gas facility in an unintentional manner. (fugitive)

- gas-to-oil ratio means the ratio of the volume of hydrocarbon gas produced, expressed in standard m3, to the volume of hydrocarbon liquid produced, expressed in standard m3. (rapport gaz-pétrole)

- hydraulic fracturing means the process of injecting fluids, or fluids mixed with solids, under pressure into a well in order to create fractures in an underground geological reservoir through which hydrocarbons and other fluids can migrate toward the well and includes hydraulic refracturing, namely, hydraulic fracturing at a well that has previously undergone hydraulic fracturing. (fracturation hydraulique)

- hydrocarbon means methane, which has the molecular formula CH4, or a volatile organic compound referred to in item 65 of the List of Toxic Substances in Schedule 1 to the Canadian Environmental Protection Act, 1999. (hydrocarbure)

- hydrocarbon gas conservation equipment means equipment used to recover hydrocarbon gas for use as fuel, for delivery or for injection for a purpose other than to dispose of the gas as waste into an underground geological deposit. (équipment de conservation de gaz d’hydrocarbures)

- legal subdivision means a unit of land consisting of one quarter of a quarter-section and having an area of approximately 16 ha or 400 m by 400 m that is described in the Dominion Lands Survey system. (subdivision officielle)

- natural gas gathering and boosting station means equipment that is located within a facility and that is used for the transportation of natural gas to a processing plant or natural gas transmission pipeline. (station de collecte et de surpression de gaz naturel)

- natural gas processing plant means a plant used for the separation of

- (a) natural gas liquids (NGLs) or non-methane gases from produced natural gas; or

- (b) NGLs into two or more mixtures, each of which consists of only those NGLs. (usine de traitement de gaz naturel)

- natural gas transmission compressor station means equipment that is located within a facility and that is used for the transportation of natural gas through a natural gas transmission pipeline. (station de compression de gaz naturel)

- operator means a person who has the charge, management or control of an upstream oil and gas facility. (exploitant)

- pneumatic controller means a device that uses pressurized gas to generate mechanical energy for the purpose of controlling or maintaining the conditions under which a process is carried out. (régulateur pneumatique)

- pneumatic pump means a device that uses pressurized gas to generate mechanical energy for the purpose of pumping liquid. (pompe pneumatique)

- ppmv means parts per million by volume. (ppmv)

- primary processing means any processing of hydrocarbons that is for the principal purpose of removing any of, or any combination of, the following:

- (a) water;

- (b) hydrocarbon liquids;

- (c) sulphur compounds; and

- (d) contaminants. (traitement primaire)

- produce, in relation to hydrocarbon gas or liquid, means to extract hydrocarbon gas or liquid from an underground geological deposit or reservoir. (produire)

- receive, in relation to hydrocarbon gas, means to receive at an upstream oil and gas facility, other than from a natural source, hydrocarbon gas that is raw or has undergone primary processing without having been subject to additional processing. (recevoir)

- standard conditions means a temperature of 15°C and a pressure of 101.325 kPa. (conditions normalisées)

- standard m3 means a cubic metre of fluid at standard conditions. (m3 normalisé)

- upstream oil and gas facility means the buildings, other structures and stationary equipment — that are located on a single site, on contiguous or adjacent sites or on sites that form a network in which a central processing site is connected by gathering pipelines with one or more well sites — for the purpose of

- (a) the extraction of hydrocarbons from an underground geological deposit or reservoir;

- (b) the primary processing of those hydrocarbons; or

- (c) the transportation of hydrocarbons — including their storage for transportation purposes — other than for local distribution.

- It includes a gathering pipeline, transmission pipeline, natural gas gathering and boosting station, natural gas transmission compressor station and natural gas processing plant. (installation de pétrole et de gaz en amont)

- venting, in relation to emissions of hydrocarbon gas, means the emission of hydrocarbon gas from an upstream oil and gas facility in a controlled manner, other than the emission of gas arising from combustion, due to

- (a) the design of equipment or operational procedures at the facility; or

- (b) the occurrence of an event that pressurizes the gas beyond the capacity of the equipment at the facility to retain the gas. (évacuation)

- well includes a well drilled to allow for the injection of fluids or fluids mixed with solids. (puits)

Interpretation of documents incorporated by reference

(2) For the purpose of interpreting any document that is incorporated by reference into these Regulations, “should”

must be read to mean “must”

and any recommendation or suggestion must be read as an obligation, unless the context requires otherwise. For greater certainty, the context of the accuracy or repeatability of a measurement can never require otherwise.

Inconsistency

(3) In the event of an inconsistency between a provision of these Regulations and any document incorporated by reference into these Regulations, that provision prevails to the extent of the inconsistency.

Documents incorporated by reference

(4) Any document that is incorporated by reference into these Regulations is incorporated as amended from time to time.

Responsibility

Operator

3 An operator for an upstream oil and gas facility must ensure that a requirement set out in these Regulations in respect of the facility or equipment at the facility — along with any related requirement in respect of recording information, keeping documents and providing reports — is complied with.

PART 1

Onshore Upstream Oil and Gas Facilities

Application

Onshore facilities

4 This Part applies in respect of upstream oil and gas facilities other than those located offshore.

General Requirements

Hydrocarbon Gas Conservation and Destruction Equipment

Hydrocarbon gas conservation equipment

5 (1) Hydrocarbon gas conservation equipment that is used at an upstream oil and gas facility must

- (a) be operated in such a manner that at least 95% of the hydrocarbon gas that is routed to the equipment — based on a calculation of the volumetric flow rates at standard conditions — is captured and conserved;

- (b) be operating continuously, other than during periods when it is undergoing normal servicing or timely repairs; and

- (c) be operated and maintained in accordance with the applicable recommendations of its manufacturer.

Exception to paragraph (1)(c)

(2) Despite paragraph (1)(c), no recommendation referred to in that paragraph need be treated as a requirement and complied with if the operator for a facility has a record that establishes that without that compliance the hydrocarbon gas conservation equipment’s ability to respect paragraph (1)(a) is unaffected.

Records — conservation equipment

6 A record in respect of any hydrocarbon gas conservation equipment used at an upstream oil and gas facility must be made that indicates

- (a) for each month during which the equipment is used, the percentage, at any given moment, of the hydrocarbon gas routed to the equipment that is captured and conserved, along with a calculation of the volumetric flow rates on which that percentage is based, with supporting documents; and

- (b) how the equipment was operated and maintained, along with an indication of any recommendations of its manufacturer for its operation and maintenance, with supporting documents.

Conserved gas — use

7 Hydrocarbon gas that has been captured and conserved in hydrocarbon gas conservation equipment must be conserved until it is

- (a) used at the facility as fuel in a combustion device that releases at most 5% of the combusted hydrocarbon gas to the atmosphere as hydrocarbon gas;

- (b) delivered; or

- (c) injected into an underground geological deposit for a purpose other than to dispose of the gas as waste.

Records — conserved gas used as fuel

8 A record in respect of any hydrocarbon gas that is combusted as fuel in a combustion device referred to in paragraph 7(a) must be made that indicates for each month during which the device is used, the percentage, at any given moment, of the combusted hydrocarbon gas that is released as hydrocarbon gas, with supporting documents, based on

- (a) tests conducted when the device operates under conditions recommended by the manufacturer for determining this percentage; or

- (b) measurements taken when the device operates under those conditions.

Hydrocarbon gas destruction equipment

9 Hydrocarbon gas destruction equipment that is used at an upstream oil and gas facility must satisfy the requirements related to the destruction of hydrocarbon gas set out in

- (a) Sections 3.6 and 7 of Version 4.5 of the guideline entitled Flaring and Venting Reduction Guideline, published by the Oil and Gas Commission of British Columbia in June 2016, if the facility is located in British Columbia;

- (b) section 3 of the directive entitled Directive S-20: Saskatchewan Upstream Flaring and Incineration Requirements, published by the Government of Saskatchewan on November 1, 2015, if the facility is located in Manitoba or Saskatchewan; and

- (c) sections 3.6 and 7 of the directive entitled Directive 060: Upstream Petroleum Industry Flaring, Incinerating, and Venting, published by the Alberta Energy Regulator on March 22, 2016, in any other case.

Records — hydrocarbon gas destruction equipment

10 A record in respect of any hydrocarbon gas destruction equipment used at an upstream oil and gas facility must be made that demonstrates, with supporting documents, that the requirements related to the destruction of hydrocarbon gas set out in the applicable document referred to in section 9 are satisfied.

Well Completion involving Hydraulic Fracturing

Application

11 (1) This section applies in respect of an upstream oil and gas facility that includes a well that undergoes hydraulic fracturing and whose production has a gas-to-oil ratio of at least 53:1, based on the most recent determination of the gas-to-oil ratio prior to the hydraulic fracturing.

No venting

(2) Hydrocarbon gas associated with flowback at a well at an upstream oil and gas facility must not be vented during flowback but must instead be captured and routed to hydrocarbon gas conservation equipment or hydrocarbon gas destruction equipment.

Exception

(3) Subsection (2) does not apply if all the gas associated with flowback at the well does not have sufficient heating value to sustain combustion.

Records — hydraulic fracturing

12 A record in respect of each well at an upstream oil and gas facility that undergoes hydraulic fracturing must be made

- (a) that indicates the gas-to-oil ratio, based on the most recent determination of the gas-to-oil ratio prior to the hydraulic fracturing;

- (b) if that gas-to-oil ratio is at least 53:1, that demonstrates, with supporting documents, that the hydrocarbon gas associated with flowback was captured and routed to hydrocarbon gas conservation equipment or hydrocarbon gas destruction equipment; and

- (c) if hydrocarbon gas associated with flowback at the well is vented, the heating value of that gas.

Non-application — British Columbia and Alberta

13 Sections 11 and 12 do not apply in respect of an upstream oil and gas facility that is located in

- (a) British Columbia, if the facility is subject to the requirements with respect to well completion involving hydraulic fracturing that are set out in the guideline entitled Flaring and Venting Reduction Guideline, published by the Oil and Gas Commission of British Columbia in June 2016; and

- (b) Alberta, if the facility is subject to the requirements with respect to well completion involving hydraulic fracturing that are set out in the directive entitled Directive 060: Upstream Petroleum Industry Flaring, Incinerating, and Venting, published by the Alberta Energy Regulator on March 22, 2016.

Compressors

Capture or venting of emissions

14 The emissions of hydrocarbon gas from the seals of a centrifugal compressor, or from the rod packings and distance pieces of a reciprocating compressor, that has a rated brake power of 75 kW or more at an upstream oil and gas facility must be

- (a) captured and routed to hydrocarbon gas conservation equipment or hydrocarbon gas destruction equipment; or

- (b) routed to vents that release those emissions to the atmosphere.

Measurement of flow rate

15 The flow rate of emissions of hydrocarbon gas released from the vents referred to in paragraph 14(b) of a compressor must be measured by means of

- (a) a flow meter, other than a calibrated bag, in accordance with section 16; or

- (b) a continuous monitoring device in accordance with section 17.

Flow meters

16 (1) The flow meter must be calibrated in accordance with the manufacturer’s recommendations such that its measurements have a maximum margin of error of ±10%.

Measurements by flow meters

(2) Those measurements must be made

- (a) in accordance with the recommendations set out in the manufacturer’s manual, if any;

- (b) in the case of a measurement made without the use of negative pressure or a vacuum, while there is a tight seal over the vent;

- (c) in the case of a measurement on a centrifugal compressor, when the compressor is operating under conditions that are representative of the conditions during the previous seven days; and

- (d) in the case of a measurement on a reciprocating compressor, when the compressor is pressurized.

Initial and subsequent measurements

(3) The flow rate must be measured within the following periods:

- (a) initially, the period that ends on

- (i) January 1, 2021, if the compressor is installed at the facility before January 1, 2020, and

- (ii) the 365th day after the day on which the compressor was installed at the facility, in any other case; and

- (b) subsequently, the period that ends on the 365th day after the day on which a previous measurement was taken.

Measurements — maximum or average

(4) The initial and each subsequent measurement of the flow rate must be based on measurements made by the flow meter over a continuous period of at least five minutes and is

- (a) the maximum of the flow rates measured, if the measurements are made over a continuous period of at least five minutes and less than 15 minutes; or

- (b) the average of the flow rates measured, if the measurements are made over a continuous period of at least 15 minutes.

Extension — not operating or not pressurized

(5) Despite subsection (3), if no measurement has been made by the last day of a period referred to in that subsection — but, on that day, the compressor is not operating, in the case of a centrifugal compressor, or the compressor is not pressurized, in the case of a reciprocating compressor — the measurement must be made under that subsection on or before the 30th day after the day on which the compressor is next operating or pressurized, as the case may be.

Extension — pressurized for < 1,314 hours per 3 years

(6) Despite subsection (3), a period referred to in that subsection is extended by 365 days if the operator for the facility makes a record that demonstrates that, during the three calendar years immediately before the end of the period, the compressor was pressurized for less than 1,314 hours, as determined by an hour meter or as recorded in a log of operations.

Continuous monitoring devices

17 A continuous monitoring device must

- (a) be calibrated in accordance with the recommendations of the manufacturer of the device such that its measurements have a maximum margin of error of ±10%;

- (b) be operated continuously, other than during periods when it is undergoing normal servicing or timely repairs; and

- (c) be equipped with an alarm that is triggered when the applicable flow rate limit referred to in subsection 18(2) or (3) for the vents of the compressor is reached.

Corrective action

18 (1) If the flow rate of emissions of hydrocarbon gas released from vents referred to in paragraph 14(b) of a compressor, measured in accordance with subsection 16(2), is greater than the applicable flow rate limit set out in subsection (2) or (3) or if the alarm referred to in paragraph 17(c) is triggered, corrective action must be taken to reduce that flow rate to below or equal to that limit, as demonstrated by a remeasurement that results,

- (a) when a flow meter is used for the remeasurement, in a reading that is below or equal to that limit; or

- (b) when a continuous monitoring device is used for the remeasurement, in the absence of an alarm when the compressor resumes operation following the taking of the corrective action.

Flow rate limit — centrifugal compressors

(2) For emissions that are from the seals of a centrifugal compressor, the flow rate limit is

- (a) if the compressor is installed on or after January 1, 2023, 0.14 standard m3/min; and

- (b) if the compressor is installed before January 1, 2023 and has a rated brake power of

- (i) greater than or equal to 5 MW, 0.68 standard m3/min, and

- (ii) less than 5 MW, 0.34 standard m3/min.

Flow rate limit — reciprocating compressors

(3) For emissions that are from the rod packings and distance pieces of a reciprocating compressor, the flow rate limit is

- (a) if the compressor is installed on or after January 1, 2023, the product of 0.001 standard m3/min and the number of pressurized cylinders that the compressor has; and

- (b) if the compressor is installed before January 1, 2023, the product of 0.023 standard m3/min and the number of those pressurized cylinders.

Remeasurement

(4) The remeasurement referred to in paragraph (1)(a) or (b) must be taken in accordance with section 15 on or before the later of

- (a) the 90th day after the day on which, as the case may be, the most recent measurement is taken under subsection 16(3) or the alarm referred to in paragraph 17(c) is triggered, and

- (b) if the estimated volume of hydrocarbon gas, expressed in standard m3, that would, beginning from the day on which the applicable day described in paragraph (a), be emitted until that next planned shutdown if no corrective action were taken is equal to or less than the volume of hydrocarbon gas, expressed in standard m3, that would be emitted due to the purging of hydrocarbon gas in order to take the corrective action,

- (i) the day on which the compressor begins to operate after the next planned shutdown, in the case of a centrifugal compressor, and

- (ii) the day on which the compressor is first pressurized after the next planned shutdown, in the case of a reciprocating compressor.

Estimated volume

(5) The estimated volume of hydrocarbon gas must be based on the most recent flow rate of emissions of hydrocarbon gas released from vents referred to in paragraph 14(b) of the compressor, as determined by a flow meter or a continuous monitoring system in accordance with section 15.

Records — compressors and vents

19 (1) A record must be made that indicates for each compressor referred to in section 14

- (a) its serial number;

- (b) its make and model;

- (c) its rated brake power;

- (d) the date on which it was installed at the facility, if it was installed on or after January 1, 2020, or a demonstration, with supporting documents, that it was installed at the facility before January 1, 2020;

- (e) if applicable, the type of hydrocarbon gas conservation equipment or hydrocarbon gas destruction equipment to which the emissions of hydrocarbon gas from the its seals or rod packing and distance pieces, as the case may be, are captured and routed, namely

- (i) a vapour recovery unit,

- (ii) a vent gas capture system,

- (iii) a flare,

- (iv) an enclosed combustor, or

- (v) another type, and if so, a description of the type;

- (f) for each centrifugal compressor for which emissions from its seals are routed to vents that release those emissions to the atmosphere, whether the seals are dry or wet;

- (g) for each reciprocating compressor from which emissions from its rod packings and distance pieces are routed to vents that release those emissions to the atmosphere, the number of those rod packings; and

- (h) for each compressor for which the period within which a measurement by a flow meter must be made has been extended under subsection 16(6), the number of hours during which it was pressurized during the three calendar years referred to in that subsection.

Records — flow meters

(2) A record must be made that indicates, for each measurement, including a remeasurement, the flow rate of emissions from a vent referred to in paragraph 14(b) made by means of a flow meter referred to in paragraph 15(a),

- (a) the make and model of the flow meter;

- (b) the maximum flow rate referred to in paragraph 16(4)(a) or the average flow rate referred to in paragraph 16(4)(b), as the case may be;

- (c) the date on which the measurement was taken;

- (d) the recommendations of the manufacturer for the calibration of the flow meter referred to in subsection 16(1), along with a demonstration, with supporting documents, that the measurements taken with that calibration have a maximum margin of error of ±10%;

- (e) any recommendation for the taking of the measurement, along with supporting documents;

- (f) the duration of the continuous period referred to in paragraph 16(4)(a) or (b), as the case may be; and

- (g) the name of the person who took the measurement and, if that person is a corporation, the name of the individual who took it.

Records — continuous monitoring devices

(3) A record must be made that indicates, for each measurement, including a remeasurement, of the flow rate of emissions from a vent referred to in paragraph 14(b) made by means of a continuous monitoring device referred to in paragraph 15(b),

- (a) a description of the device;

- (b) if applicable, its serial number, make and model; and

- (c) the recommendations of the manufacturer for the calibration of the continuous monitoring device referred to in paragraph 17(a) along with a demonstration, with supporting documents, that the measurements taken with that calibration have a maximum margin of error of ±10%.

Records — corrective actions taken

(4) A record must be made that indicates, for each corrective action taken,

- (a) a description of the corrective action, including a description of each step of the corrective action;

- (b) the dates on which that corrective action was taken, along with the dates on which each of its steps was taken;

- (c) for each remeasurement taken under paragraph 18(4)(b), the volume and estimated volume, determined for the purpose of that paragraph, along with supporting calculations; and

- (d) if the corrective action was taken as a result of a measurement by means of a continuous monitoring device, the date on which the alarm was triggered.

Conditional Requirements

Conditions

Application of sections 26 to 45

20 (1) Sections 26 to 45 apply in respect of an upstream oil and gas facility as of the first day of the month that begins after the facility produces or receives — or is expected to produce or receive — a combined volume of more than 60 000 standard m3 of hydrocarbon gas for a period of 12 months, determined as follows:

- (a) if the facility has operated during at least 12 months, whether consecutive or not, with at least one day of operation in each of those months, the combined volume of hydrocarbon gas, expressed in standard m3, produced or received based on records, for the most recent 12 of those months of operation;

- (b) if the facility has operated during at least one month and less than 12 months, whether consecutive or not, with at least one day of operation in each of those months, the combined volume of hydrocarbon gas, expressed in standard m3, that the facility is expected to produce or receive for a 12-month period determined by prorating the combined volume, based on records, produced or received during those months of operation; and

- (c) in any other case, the combined volume of hydrocarbon gas, expressed in standard m3, that the facility is expected to produce or receive during the 12-month period that begins after its first month of operation, as determined in accordance with the applicable method set out in section 23.

Well completion

(2) For the purpose of subsection (1), if a well at the facility undergoes well completion during a given month, the portion of the combined volume referred to in that subsection that corresponds to the production of hydrocarbon gas from the well must be based on the volume of hydrocarbon gas expected to be produced by the well for the 12-month period after the given month, as determined in accordance with the applicable method set out in section 23.

Records — non-application

21 If none of sections 26 to 45 apply, for a given month, in respect of an upstream oil and gas facility, a record, with supporting documents, must be made that indicates

- (a) the gas-to-oil ratio and the volume of the hydrocarbon liquid produced or expected to be produced, expressed in standard m3, during the given month;

- (b) the combined volume of hydrocarbon gas produced and received, expressed in standard m3, during the given month; and

- (c) for a well at the facility that undergoes well completion during the given month, the volume expected to be produced by the well referred to in subsection 20(2).

Records — application

22 A record must be made that indicates the following information for the first month that begins after the facility produces or receives — or is expected to produce or receive — a combined volume of more than 60 000 standard m3 of hydrocarbon gas for a period of 12 months as determined in accordance with subsection 20(1):

- (a) that first month and the calendar year that includes that first month; and

- (b) the combined volume, along with an indication as to which of paragraphs 20(1)(a) to (c) was used to determine that volume.

Determination of Volume of Gas

Applicable methods

23 (1) For the purpose of sections 20 and 26, the volume of hydrocarbon gas produced, received, vented or destroyed at, or delivered from, an upstream oil and gas facility must be determined in accordance with the applicable method set out in

- (a) the document entitled Measurement Guideline for Upstream Oil and Gas Operations, published by the Oil and Gas Commission of British Columbia on March 1, 2017, if the facility is located in British Columbia;

- (b) the document entitled Measurement Requirements for Oil and Gas Operations and commonly referred to as Directive PNG017, published by the Government of Saskatchewan on August 1, 2017 (version 2.1), if the facility is located in Manitoba or Saskatchewan; and

- (c) the document entitled Measurement Requirements for Oil and Gas Operations and commonly referred to as AER Directive 017, published by the Alberta Energy Regulator on March 31, 2016, in any other case.

Directive PNG017 and AER 017

(2) Despite paragraphs (1)(b) and (c), for the purpose of sections 12.2.2.1 and 12.2.2.2 of the Saskatchewan Directive PNG017 and of the AER Directive 017, the gas production per well per day is to be determined

- (a) if the expected gas production is greater than 2 000 standard m3 per day, by direct measurement; and

- (b) in any other case,

- (i) by direct measurement, or

- (ii) by means of an estimate based on a gas-to-oil ratio determined

- (A) in accordance with section 24, or

- (B) by the formula

−0.5Pw + 150

- where

- Pwis the average volume, expressed in standard m3, of oil produced by the well for a day during the most recent month of production.

Determination of gas-to-oil ratio

24 (1) The determination of a gas-to-oil ratio for the purpose of clause 23(2)(b)(ii)(A) is made using the formula

G/O

- where

- G is the average volume of gas produced by the well measured over a continuous period — of at least 72 hours or at least 24 hours, determined, as the case may be, in accordance with subsection (2) or (3) — under conditions, in particular in respect of flow rate and operating conditions, that are representative of the conditions that occurred during the most recent month of production; and

- O is the average volume of oil produced by the well over the period that is used for the determination of G, based on measurements taken in accordance with subsection (4) as prorated to that period and under conditions, in particular in respect of flow rate and operating conditions, that are representative of the conditions during the most recent month of production.

Determination of value of G

(2) The measurements to determine the value of G must be taken over a continuous period of at least 72 hours with a continuous measuring device or using a flow meter with at least one reading taken every 20 minutes.

Exception

(3) Despite subsection (2), the measurements to determine the value of G may be taken over a continuous period of at least 24 hours, if

- (a) the flow rate of gas from the well is greater than 100 standard m3 per day; and

- (b) the measurement is taken

- (i) with a continuous measuring device and the variation of flow rate in that continuous period is such that the average flow rate for any 20-minute period is within ±5% of the average flow rate, or

- (ii) using a flow meter with at least one reading taken every 20 minutes within that continuous period and the variation of flow rate in that continuous period is such that 95% of the readings taken are within ±5% of the average flow rate.

Determination of the value of O

(4) The measurements to determine the value of O must be taken after the water has been separated from the liquid produced from the well and taken

- (a) over the continuous period used to determine the value of G with a continuous measuring device that has a maximum margin of error of ±0.1 standard m3; or

- (b) over a continuous period of at least 10 days that includes the continuous period used to measure G with a continuous measuring device that has a maximum margin of error of ±1 standard m3 and with the variation of flow rate in that continuous period such that the measured volume of oil produced for any day is within ±5% of the measured volume of oil produced for any other day in that continuous period.

Steady state

(5) A measurement taken under any of subsections (2) to (4) must be taken while the well is operating in a steady state, that is, it must be taken only if no adjustment that could result in a change to the oil or gas production rates has been made to the production parameters for at least 48 hours before the measurement is taken.

Measuring equipment — directives

(6) The continuous measuring device or flow meter used to determine the gas-to-oil ratio must meet the requirements of section 2 of the Saskatchewan Directive PNG017 or section 2 of the AER Directive 017.

Frequency of determination

(7) A determination of the gas-to-oil ratio must be made

- (a) at least once per year and at least 90 days after a previous determination, if

- (i) in the case of an initial determination, the expected flow rate of the gas is at most 500 standard m3 per day, and

- (ii) in any other case, the flow rate of the gas according to the most recent determination was at most 500 standard m3 per day;

- (b) at least once every six months and at least 45 days after a previous determination, if

- (i) in the case of an initial determination, the expected flow rate of the gas is greater than 500 standard m3 per day and at most 1 000 standard m3 per day, and

- (ii) in any other case, the flow rate of the gas according to the most recent determination was greater than 500 standard m3 per day and at most 1 000 standard m3 per day; and

- (c) at least once every month and at least seven days after a previous determination, if

- (i) in the case of an initial determination, the expected flow rate of the gas is greater than 1 000 standard m3 per day and at most 2000 standard m3 per day, and

- (ii) in any other case, the flow rate of the gas according to the most recent determination was greater than 1 000 standard m3 per day and at most 2 000 standard m3 per day.

Records

25 A record must be made that indicates

- (a) all of the readings from a continuous measuring device and each reading taken using a flow meter;

- (b) the flow rate over each period during which measurements were taken for each determination of the value of G and O;

- (c) the dates, time and duration of each of those periods;

- (d) the production parameters during each of those periods and the 48 hours before each of those periods begins; and

- (e) whether the type of equipment used to take each measurement was a continuous measuring device or a flow meter and its make and model.

Venting Limit

15 000 standard m3 per year

26 (1) An upstream oil and gas facility must not vent more than 15 000 standard m3 of hydrocarbon gas during a year.

Excluded volumes

(2) The volumes of hydrocarbon gas vented that arose from the following activities are excluded from the determination of the volume vented for the purpose of subsection (1):

- (a) liquids unloading, that is, the removal of accumulated liquids from a gas well;

- (b) a blowdown, that is, the temporary depressurization of equipment or pipelines;

- (c) glycol dehydration, that is, the use of a liquid desiccant system to remove water from natural gas or natural gas liquids;

- (d) the use of a pneumatic controller, pneumatic pump or compressor;

- (e) the start-up and shutdown of equipment;

- (f) well completion; and

- (g) venting in order to avoid serious risk to human health or safety arising from an emergency situation.

Non-application of subsection (1)

(3) Subsection (1) does not apply in respect of a facility, as of a given month, if the combined volume of hydrocarbon gas that was vented or destroyed at, or delivered from, the facility was less than 40 000 standard m3 for the 12 consecutive months before that given month.

Re-application of subsection (1)

(4) Despite subsection (3), subsection (1) does apply in respect of a facility referred to in subsection (3), as of a subsequent month, if the combined volume of hydrocarbon gas that was vented or destroyed at, or delivered from, the facility was equal to or greater than 40 000 standard m3 for the 12 consecutive months before that subsequent month.

Records — volumes of hydrocarbon gas

27 For each month that an upstream oil and gas facility operates, a record, with supporting documents, must be made that indicates

- (a) the volume of hydrocarbon gas that was vented, expressed in standard m3;

- (b) the volume of hydrocarbon gas vented that arose from the activities referred to in each of paragraphs 26(2)(a) to (g);

- (c) the volume of hydrocarbon gas destroyed at the facility, expressed in standard m3; and

- (d) the volume of hydrocarbon gas delivered from the facility, expressed in standard m3.

Leak Detection and Repair Program

Establishment of Program

Non-application to certain equipment components

28 (1) Sections 29 to 36 do not apply in respect of

- (a) an equipment component used on a wellhead at a site at which there is no other wellhead or equipment except for gathering pipelines or a meter connected to the wellhead;

- (b) a pair of isolation valves on a transmission pipeline if no other equipment is located on the segment of the pipeline that may be isolated by closing the valves; and

- (c) an equipment component used at an upstream oil and gas facility whose inspection would pose a serious risk to human health or safety.

Record

(2) A record must be made that indicates whether an equipment component is an equipment component referred to in any of paragraphs (1)(a) to (c).

Regulatory or alternative LDAR programs

29 (1) An operator for a facility must — in order to limit fugitive emissions containing hydrocarbon gas from equipment components at the facility — establish and carry out at the facility

- (a) a regulatory leak detection and repair program that satisfies the requirements of sections 30 to 33; or

- (b) an alternative leak detection and repair program referred to in subsection 35(1) that results in at most the same quantity of those fugitive emissions as would result from a regulatory program referred to in paragraph (a), as demonstrated in a record, with supporting documents, made by the operator before the program is established and, at least once per year and at least 90 days after a previous demonstration, while the program is being carried out.

Notice to Minister

(2) An operator for a facility that establishes a leak detection and repair program referred to in paragraph (1)(b) must, without delay, notify the Minister to that effect.

Regulatory LDAR Programs

Obligation to inspect

30 (1) An equipment component at an upstream oil and gas facility must be inspected, during the periods referred to in subsection (3), for the release of hydrocarbons by means of an eligible leak detection instrument.

Eligible leak detection instruments

(2) The following leak detection instruments are eligible:

- (a) a portable monitoring instrument if it

- (i) meets the specifications set out in Section 6 of EPA Method 21,

- (ii) is operated in accordance with the requirements of Section 8.3 of EPA Method 21 to the extent that those requirements are consistent with its manufacturer’s recommendations,

- (iii) is calibrated in accordance with Sections 7, 8.1, 8.2 and 10 of EPA Method 21 before it is used, for each day on which it is used, and

- (iv) undergoes a calibration drift assessment after its last use on each of those days in accordance with the requirements set out in Section 60.485a(b)(2) of Subpart VVa, entitled Standards of Performance for Equipment Leaks of VOC in the Synthetic Organic Chemicals Manufacturing Industry for which Construction, Reconstruction, or Modification Commenced After November 7, 2006, in Part 60 of Title 40, Chapter I of the Code of Federal Regulations of the United States; and

- (b) an optical gas-imaging instrument if it is capable of imaging gas that is

- (i) in the spectral range for the compound of highest concentration in the hydrocarbon gas to be measured,

- (ii) half methane and half propane at a total concentration of at most 500 ppmv and at a flow rate of at least 60 g/h leaking from an orifice that is 0.635 cm in diameter, and

- (iii) at the viewing distance determined in accordance with the requirements of the alternative work practice of the Environmental Protection Agency of the United States set out in Sections 60.18(h)(7)(i)(2)(i) to (v) of Section 60.18, entitled General control device and work practice requirements, in Part 60 of Title 40, Chapter I of the Code of Federal Regulations of the United States.

Period for inspections

(3) The period for inspections is as follows:

- (a) for the first inspection, on or before the later of May 1, 2020 and the day that occurs 60 days after the day on which production at the facility first began; and

- (b) for subsequent inspections, at least three times per year and at least 60 days after a previous inspection.

Operation and maintenance

(4) An eligible leak detection instrument must be operated and maintained in accordance with the recommendations, if any, of its manufacturer.

Training

(5) The inspection must be conducted by an individual who, not more than five years before the inspection, has received training in

- (a) the operation and maintenance, in accordance with subsection (4), of eligible leak detection instruments; and

- (b) the calibration requirements set out in subparagraphs (2)(a)(iii) and (iv), if an eligible portable monitoring instrument is used.

Leaks

31 (1) A release of hydrocarbons from an equipment component is a leak if

- (a) the release consists of at least 500 ppmv of hydrocarbons, as determined by an inspection conducted by means of an eligible portable monitoring instrument in accordance with EPA Method 21; or

- (b) the release is detected

- (i) during an inspection conducted by means of an eligible optical gas-imaging instrument, or

- (ii) by means of an auditory method, an olfactory method or a visual method, including the observation of the dripping of hydrocarbon liquids from the equipment component.

Release not considered a leak

(2) A release that is detected under paragraph (1)(b) is no longer considered to be a leak if the equipment component undergoes an inspection conducted by means of an eligible portable monitoring instrument in accordance with EPA Method 21 and the release is determined to consist of less than 500 ppmv of hydrocarbons.

Period for repair

32 (1) A leak from an equipment component that is detected, whether as a result of an inspection or otherwise, must be repaired

- (a) if the repair can be carried out while the equipment component is operating, within 30 days after the day on which it was detected; and

- (b) in any other case, within the period before the end of the next planned shutdown unless that period is extended under section 33.

Next planned shutdown

(2) The next planned shutdown must be scheduled not later than the date on which the estimated volume of hydrocarbon gas, expressed in standard m3, that, beginning from the day on which the leak is detected, would if no repairs are made be emitted from the leaking equipment component in question and from all other equipment components that are also leaking as of that day is equal to the volume of hydrocarbon gas, expressed in standard m3, that would be emitted due to purging of hydrocarbon gas from equipment components in order to carry out the repair.

Repair

(3) A leak in an equipment component is considered to be repaired if the release is determined to consist of less than 500 ppmv of hydrocarbons based on an inspection of the equipment component by means of an eligible portable monitoring instrument in accordance with EPA Method 21 that is capable of measuring hydrocarbon concentrations in ppmv.

Extension up to six months for repair

33 (1) An operator for an upstream oil and gas facility that must repair an equipment component on or before the end of a period referred to in paragraph 32(1)(b) may, not later than 45 days before the end of the period, apply to the Minister to extend the period for up to six months.

Granting of extension

(2) The Minister must grant the application and extend the period for up to six months if the application contains the information set out in Schedule 1 and

- (a) documents that establish that, as of the making of the application, there are reasonable grounds to conclude that it is not technically feasible to complete the repair of the equipment component before the end of the next planned shutdown;

- (b) documents that establish that the applicant has a plan to repair the equipment component that sets out

- (i) the expected date for the completion of the repair,

- (ii) the steps to be taken to ensure completion of the repair on or before that date,

- (iii) a justification, with supporting documents, for the belief that that date is the earliest feasible date to complete the repair, and

- (iv) measures to be taken to minimize, if not eliminate, any harmful effect on the environment or human health from the emission of hydrocarbon gas before the completion of the repair; and

- (c) a statement that the implementation of the plan is to begin within 30 days after the day on which the extension is granted.

Renewal

(3) The period granted under subsection (2) may be further extended by application made under subsection (1). At most two applications for a further extension may be made.

Refusal of application

(4) The Minister must refuse the application if the Minister has reasonable grounds to believe that the applicant has provided false or misleading information in the application.

Revocation of extension

34 (1) The Minister must revoke the extension granted under subsection 33(2) if the Minister has reasonable grounds to believe that the applicant has provided false or misleading information in their application for the extension.

Conditions for revocation

(2) The Minister must not revoke the extension unless the Minister has provided the applicant with

- (a) written reasons for the proposed revocation; and

- (b) an opportunity to be heard, by written representation, in respect of the proposed revocation.

Alternative LDAR Programs

Requirements for alternative program

35 (1) The alternative leak detection and repair program must include measures respecting

- (a) the inspection for leaks;

- (b) the operation, maintenance and calibration of leak detection instruments, if applicable; and

- (c) the repair of leaks detected.

Reversion to regulatory program

(2) An operator for a facility that has not made a demonstration required by paragraph 29(1)(b) must establish and carry out a regulatory leak detection and repair program.

Records

Regulatory LDAR programs

36 (1) A record, with supporting documents, must be made of the following information related to the carrying out of a regulatory leak detection and repair program:

- (a) for each calibration of an eligible leak detection instrument,

- (i) the dates of the calibration,

- (ii) the result of each calibration drift assessment, and

- (iii) the name, job title, if any, and address of the individual who carried out the calibration;

- (b) for each inspection of an equipment component,

- (i) the date of the inspection, along with the name of the individual who conducted it,

- (ii) the type of equipment component,

- (iii) the location of the equipment component within the facility or the Global Positioning System (GPS) coordinates, to five decimal places, of the equipment component,

- (iv) the type of leak detection instrument used to conduct the inspection, including, if any, its make and model,

- (v) in the case that an optical gas-imaging instrument referred to in subparagraph 31(1)(b)(i) was used to conduct the inspection, the images recorded with an embedded indication of the date and time when they were recorded, along with the location of the place where they were recorded within the facility or the GPS coordinates, to five decimal places, of the place, and

- (vi) in the case that an inspection resulted in the detection of a leak, an indication of the means, among those set out in subsection 31(1), by which the leak was detected and, in the case of a leak detected by a means set out in paragraph 31(1)(b), an indication as to whether the release was determined in accordance with subsection 31(2) to consist of less than 500 ppmv and, if so, the date of that determination, the name of the person who made that determination — and if that person is a corporation, the name of the individual who made it — and its result, expressed in ppmv, along with the make and model, if any, of the instrument used to make that determination;

- (c) for each leak detected by means of a method set out in paragraph 31(1)(b) that was not as a result of an inspection,

- (i) an indication of whether the method was auditory, olfactory or visual,

- (ii) the date on which the leak was detected, along with the name of the individual who detected it,

- (iii) the type of equipment component,

- (iv) the location of the equipment component within the facility or its GPS coordinates, to five decimal places, and

- (v) an indication as to whether the release was determined in accordance with subsection 31(2) to consist of less than 500 ppmv and, if so, the date of that determination, the name of the person who made that determination — and if that person is a corporation, the name of the individual who made it — and its result, expressed in ppmv, along with the make and model, if any, of the instrument used to make that determination;

- (d) for each individual who conducted an inspection and who received training in the operation and maintenance or in the calibration of leak detection instruments,

- (i) their name, along with the name and business address of their employer, if their employer is not the operator,

- (ii) the name and business address of the entity that provided the training, along with the name and job title of the individuals who provided it,

- (iii) the dates on which the training was provided and, for each of those dates, the number of hours of training, and

- (iv) a description of the training;

- (e) for each repair of a leak from an equipment component,

- (i) a description of the steps that were taken to repair the leak, along with the dates on which those steps were taken, and

- (ii) the result, expressed in ppmv, obtained following an inspection by means of an eligible portable monitoring system in accordance with EPA Method 21, along with the date on which that result was obtained; and

- (f) for each repair that was not carried out within 30 days after the detection of the leak:

- (i) an indication as to why the equipment component could not be repaired while it was operating, and

- (ii) if applicable, the date determined in accordance with subsection 32(2), along with the information and calculation on which that determination was based.

Alternative LDAR programs

(2) A record, with supporting documents, must be made of the following information related to the carrying out of an alternative leak detection and repair program:

- (a) the date on which each inspection was conducted and, if applicable, the name of the person who conducted it;

- (b) the type of equipment component that was inspected, along with its location within the facility or its GPS coordinates, to five decimal places;

- (c) a description as to the means by which the leak was identified;

- (d) if applicable, for each leak detection instrument used, a description of the operation, maintenance and calibration measures in relation to that instrument, along with the dates of its maintenance and calibrations and the names of the persons who carried out the maintenance and calibrations;

- (e) for each repair of a leak from an equipment component,

- (i) a description of the steps that were taken to repair the leak, along with the dates on which those steps were taken, and

- (ii) the result obtained after the repair following an inspection, along with a description of the means by which that inspection was conducted, its date and, if applicable, the name of the person who conducted it; and

- (f) the demonstrations referred to in paragraph 29(1)(b).

Document-keeping

(3) A copy of each recommendation of the manufacturer for the operation and maintenance, if any, of each eligible leak detection instrument that is used must be kept.

Pneumatic Controllers and Pneumatic Pumps

Pneumatic controllers — bleed rate

37 (1) A pneumatic controller at an upstream oil and gas facility must not operate using hydrocarbon gas, other than propane, unless

- (a) it is operated at an operational setting such that its bleed rate for that operational setting is less than or equal to 0.17 standard m3/h according to the manufacturer’s operating manual or according to a written demonstration, with supporting documents, made by the operator for the facility; or

- (b) the hydrocarbon emissions from it are captured and routed to hydrocarbon gas conservation equipment or hydrocarbon gas destruction equipment.

Exception — control of production processes

(2) Despite paragraph (1)(a), a pneumatic controller at an upstream oil and gas facility may operate using hydrocarbon gas, other than propane, at an operational setting such that its bleed rate for that operational setting is more than 0.17 standard m3/h if the operator for the facility has a written record, with supporting documents, that demonstrates that the pneumatic controller must operate at that operational setting because of the need for the pneumatic controller to have a sufficient response time to control a process in the facility’s production activities.

Records — pneumatic controllers

38 A record in respect of each pneumatic controller used at an upstream oil and gas facility that operates using hydrocarbon gas must be made that indicates

- (a) the identifier for the pneumatic controller;

- (b) whether the pneumatic controller is used

- (i) for controlling pressure or flow rate,

- (ii) for controlling liquid levels,

- (iii) for controlling temperature,

- (iv) as a transducer,

- (v) as a positioner, or

- (vi) as an emergency response device, or

- (vii) for another purpose or as another device and, if so, the purpose or type of device; and

- (c) the design bleed rate for the pneumatic controller’s operational setting, including its supply pressure and, if any, its band setting, or its bleed rate according to a written demonstration, with supporting documents, made by the operator for the facility at which the controller is used.

Pneumatic pumps

39 (1) Unless an operator for an upstream oil and gas facility has a permit issued in accordance with subsection 40(2), a pneumatic pump or a group of pneumatic pumps, used at the facility that pumps methanol into a common stream or an equipment component — must not operate using hydrocarbon gas if the pump or the group of pumps has, in a month, pumped more than 20 L of methanol per day on average over the month.

Demonstration of quantity of liquid pumped

(2) An operator for the facility must, for each pump or group of pumps referred to in subsection (1) that operates during a month at the facility, demonstrate the quantity of liquids that it pumped, on average, per day over the month by means of

- (a) a record that indicates the quantity of liquid pumped during that month; or

- (b) documents that establish that the pump or the group of pumps could not have pumped more than 20 L of liquid per day on average over the month.

When subsection (2) no longer applies

(3) Subsection (2) no longer applies in respect of a pump or group of pumps as of the end of a month during which it operated at the facility and records establish that it pumped, or could have pumped, more than 20 L of liquid per day on average over the month.

Non-application of subsections (1) and (2)

(4) Subsections (1) and (2) do not apply in respect of any pneumatic pump if hydrocarbon emissions from it are captured and routed to hydrocarbon gas conservation equipment or hydrocarbon gas destruction equipment.

Permit — pneumatic pumps

40 (1) An operator for an upstream oil and gas facility may, on or before June 30, 2022, apply to the Minister for a permit to have a pneumatic pump at the facility operate using hydrocarbon gas while its hydrocarbon emissions are not captured and routed to hydrocarbon gas conservation equipment or hydrocarbon gas destruction equipment.

Issuance of permit

(2) The Minister must issue the permit if the application contains the information set out in Schedule 2 and documents that establish that

- (a) there are reasonable grounds to conclude that it is not feasible, technically or economically, for the applicant to have the pneumatic pump operate at the facility without using hydrocarbon gas or to have the pneumatic pump function using hydrocarbon gas while its hydrocarbon emissions are captured and routed to hydrocarbon gas conservation equipment or hydrocarbon gas destruction equipment, including grounds based on

- (i) the capital, operating and maintenance costs of any modifications at the facility to achieve that objective, and

- (ii) the avoided costs and any economic benefits arising from the incurring of those capital, operating and maintenance costs; and

- (b) the applicant has a plan that

- (i) involves taking steps to minimize the emission of hydrocarbon gas from the pneumatic pump, including steps such as adjusting the capacity of the pump or its operational settings so as to achieve the desired rate of injection of chemicals from the pump with the least possible emissions, along with a schedule to implement the plan, and

- (ii) can reasonably be regarded as feasible for the purpose of permitting the facility to comply with subsection 39(1) on or before January 1, 2026.

Duration

(3) A permit takes effect on January 1, 2023 and expires on the earliest of

- (a) the day on which the pneumatic pump ceases to function using hydrocarbon gas,

- (b) the day on which the hydrocarbon emissions from the pneumatic pump begin to be captured and routed to hydrocarbon gas conservation equipment or hydrocarbon gas destruction equipment, and

- (c) December 31, 2025.

Refusal of application

(4) The Minister must refuse the application if the Minister has reasonable grounds to believe that the applicant has provided false or misleading information in the application.

Tagging

41 (1) A pneumatic controller that is referred to in subsection 37(2) or a pneumatic pump referred to in a permit issued under subsection 40(2) must be tagged to indicate that it is not subject to subsection 37(1) or 39(1) or an entry to that effect must be made in an electronic tracking system.

Identifier

(2) The tag or the entry must also include an identifier for the pneumatic controller or the pneumatic pump.

Other Equipment

Pipes and hatches

42 A hatch and the open end of a pipe at an upstream oil and gas facility must be closed — other than during an operation at the facility that requires the hatch or pipe to be open — in such a way as to minimize the emission of hydrocarbon gas.

Sampling systems and pressure relief devices

43 A sampling system or a pressure relief device used at an upstream oil and gas facility must be installed and operated in such a way as to minimize the emission of hydrocarbon gas from the system or the pressure relief device.

Records — hatches, pipes, systems and devices

44 A record must be made that indicates whether an upstream oil and gas facility has a hatch, a pipe with an open end or uses a sampling system or pressure relief device.

Revocation of Permit

Subsection 40(2)

45 (1) The Minister must revoke a permit issued under subsection 40(2) if the Minister has reasonable grounds to believe that the applicant has provided false or misleading information in their application for the permit.

Conditions for revocation

(2) The Minister must not revoke a permit unless the Minister has provided the applicant with

- (a) written reasons for the proposed revocation; and

- (b) an opportunity to be heard, by written representation, in respect of the proposed revocation.

PART 2

Offshore Upstream Oil and Gas Facilities

Application

Offshore facilities

46 (1) This Part applies in respect of upstream oil and gas facilities located offshore.

Non-application

(2) Despite subsection (1), this Part does not apply in respect of an offshore facility if

- (a) a regulation is made under the Canada–Newfoundland and Labrador Atlantic Accord Implementation Act or the Canada-Nova Scotia Offshore Petroleum Resources Accord Implementation Act that applies in respect of the offshore facility and imposes requirements that are at least as stringent as those set out in sections 47 to 53; and

- (b) the title of the regulation is published in the environmental registry established under section 12 of the Canadian Environmental Protection Act, 1999 for the purpose of this subsection.

Venting Limit

15 000 standard m3 per year

47 (1) An offshore facility must not vent more than 15 000 standard m3 of hydrocarbon gas during a year.

Excluded volume — health or safety

(2) Any volume of hydrocarbon gas that is vented from the offshore facility in order to avoid serious risk to human health or safety arising from an emergency situation is excluded from the determination of the volume vented for the purpose of subsection (1).

Records — annual volume vented

48 (1) For each year that an offshore facility operates, a record, with supporting documents, must be made that indicates the volume of hydrocarbon gas that was vented, expressed in standard m3.

Records — emergency situation

(2) For each volume of vented hydrocarbon gas arising from an emergency situation referred to in subsection 47(2), a record must be made that indicates:

- (a) the name of the offshore facility;

- (b) the volume of hydrocarbon gas that was vented, expressed in standard m3; and

- (c) a description of the emergency situation.

Compressors

Capture or venting of emissions

49 The emissions of hydrocarbon gas from the seals of a centrifugal compressor at an offshore facility must be

- (a) captured and routed to hydrocarbon gas conservation equipment or hydrocarbon gas destruction equipment; or

- (b) routed to vents that release those emissions to the atmosphere.

Continuous monitoring devices

50 (1) The flow rate of emissions of hydrocarbon gas from vents referred to in paragraph 49(b) must be measured by means of a continuous monitoring device.

Requirements

(2) A continuous monitoring device must

- (a) be calibrated in accordance with the manufacturer’s recommendations such that its measurements have a maximum margin of error of ±10%;

- (b) be operated continuously, other than during periods when it is undergoing normal servicing or timely repairs; and

- (c) be equipped with an alarm that is triggered when the applicable flow rate limit referred to in subsection (3) for the vents of the compressor is reached.

Flow rate limit

(3) The flow rate limit of emissions of hydrocarbon gas from the vents of a compressor is

- (a) for a compressor that was installed before January 1, 2023,

- (i) 0.68 standard m3/min, if the compressor has a rated brake power of greater than or equal to 5 MW, and

- (ii) 0.34 standard m3/min, if the compressor has a rated brake power of less than 5 MW; and

- (b) for a compressor that was installed on or after January 1, 2023, 0.14 standard m3/min.

Corrective action

(4) If the alarm is triggered, corrective action must be taken to reduce the flow rate to below or equal to the applicable flow rate limit, as demonstrated by the absence of an alarm when the compressor begins to operate following the taking of that action.

Records

51 A record must be made that indicates the following information concerning centrifugal compressors:

- (a) for each compressor referred to in section 49,

- (i) its serial number,

- (ii) its make and model,

- (iii) whether it was installed at the facility before January 1, 2023 or on or after January 1, 2023,

- (iv) if it was installed at the facility before January 1, 2023, its rated brake power, and

- (v) an indication of the manufacturer’s recommendations for the calibration of the continuous monitoring device, along with a demonstration, with supporting documents, that the measurements taken with that calibration have a maximum margin of error of ±10%;

- (b) for each compressor for which an alarm referred to subsection 50(4) was triggered,

- (i) its serial number, make and model,

- (ii) the date on which the alarm was triggered,

- (iii) the flow rate indicated by the continuous monitoring device when the alarm was triggered, and

- (iv) a description of the corrective action that was taken, along with the dates on which that action was taken.

Gas Detection System and Repair of Leaks

Requirements

52 (1) An offshore facility must be equipped with a gas detection system that satisfies the requirements of section 32 of the Newfoundland Offshore Petroleum Installations Regulations and section 32 of the Nova Scotia Offshore Petroleum Installations Regulations.

Repair

(2) A leak must be repaired within 730 days after the day on which it is detected by the gas detection system or is detected by means of an auditory method, an olfactory method or a visual method, including the observation of the dripping of hydrocarbon liquids from the equipment component.

Records

53 A record must be made that indicates the following information concerning the detection and repair of leaks:

- (a) the date on which each leak was detected;

- (b) the type of equipment that was leaking, along with its location within the facility or its identifier;

- (c) the means by which the leak was identified; and

- (d) the steps that were taken to repair each leak detected, along with the dates on which those steps were taken.

PART 3

Administration

Registration

Registration report

54 (1) An upstream oil and gas facility in respect of which any of sections 5, 9, 11, 14 and 15 apply or in respect of which sections 26 to 45 apply and an offshore facility in respect of which section 46 applies must be registered by providing the Minister with a registration report for the facility that contains the information set out in Schedule 3.

Date of registration

(2) The facility must be registered not later than 120 days after the later of

- (a) January 1, 2020, and

- (b) the earlier of

- (i) the first day on which any of sections 5, 9, 11, 14, 15 and 46 apply in respect of the facility, and

- (ii) the first day of the month referred to in subsection 20(1) as of which sections 26 to 45 apply in respect of the facility.

Updated information

(3) If there is a change such that the information provided in the facility’s registration report is no longer accurate, a notice to that effect that contains the updated information, along with the information referred to in item 4 of Schedule 3, must be sent to the Minister not later than 90 days after the change.

Provision of information

55 (1) Information that is required under section 54 to be in a registration report provided to the Minister may be provided to the Minister via an approved entity.

Deemed provision of registration report

(2) If all of the information required to be in a registration report is provided to the Minister via an approved entity, the operator for that facility must notify the Minister to that effect. The registration report is deemed to have been provided to the Minister on the day on which the Minister receives that notice.

Approval of entity

(3) The Minister may approve an entity for the purpose of subsection (1) if the Minister concludes an arrangement with the entity under which information referred to in section 54 that is provided to the entity is accessible to the Minister.

Publication of approved entities

(4) The Minister must publish a list of approved entities in the Environmental Registry established under section 12 of the Canadian Environmental Protection Act, 1999.

Withdrawal of approval

(5) The Minister may withdraw the approval of an entity and publish a notice to that effect in the Environmental Registry.

Record-making and Updating and Keeping of Documents

Record-making and updates

56 (1) A record that is required to be made under these Regulations must be made within 30 days after the day on which the information to be recorded becomes available. The record must be updated within 30 days after the information to be updated becomes available.

Record-keeping — indefinite

(2) A record, along with supporting documents, of information that applies on an ongoing basis must be kept indefinitely until an update is required.

Record-keeping — five years

(3) If an update referred to in subsection (2) is required, the record of the information, along with its supporting documents, as recorded before the updating must be kept for five years after the updating.

Record-keeping — five years

(4) A record, along with supporting documents, of information that applies only in respect of a given day, must be kept for five years after that given day.

Document-keeping

(5) A document that is required to be kept under these Regulations must be kept for five years.

Place kept

(6) The records and documents must be kept at the upstream oil and gas facility to which they relate or at another place in Canada where they can be inspected.

Provision of records

(7) On the Minister’s request, the operator must, within 60 days after the day on which the request was made, provide any of the records or documents kept to the Minister.

Consequential Amendment to the Regulations Designating Regulatory Provisions for Purposes of Enforcement (Canadian Environmental Protection Act, 1999)

57 The schedule to the Regulations Designating Regulatory Provisions for Purposes of Enforcement (Canadian Environmental Protection Act, 1999) footnote1 is amended by adding the following in numerical order:

| Item |

Column 1 |

Column 2 |

|---|---|---|

30 |

Regulations Respecting Reduction in the Release of Methane |

(a) subsection 5(1) (b) section 6 (c) section 7 (d) section 8 (e) section 9 (f) section 10 (g) subsection 11(2) (h) section 12 (i) section 14 (j) section 15 (k) paragraphs 19(1)(a), (c), (d), (f), (g) and (h), subsection 19(2) and paragraphs 19(4)(b) and (c) (l) section 20 (m) section 21 (n) section 22 (o) section 25 (p) subsection 26(1) (q) section 27 (r) subsection 30(1) and (3) (s) subsection 32(1) (t) subsection 35(1) (u) section 36 (v) subsections 37(1) and (2) (w) section 38 (x) subsections 39(1) and (2) (y) section 42 (z) section 43 (z.1) subsection 47(1) |

(z.2) section 48 (z.3) section 49 (z.4) subsection 50(3) (z.5) section 51 (z.6) section 52 (z.7) section 53 |

Coming into Force

January 1, 2020

58 (1) Subject to subsection (2), these Regulations come into force on January 1, 2020.

January 1, 2023

(2) Sections 26, 27 and 37 to 41 of these Regulations and paragraphs 32(p), (q), (v), (w) and (x) of the schedule to the Regulations Designating Regulatory Provisions for Purposes of Enforcement (Canadian Environmental Protection Act, 1999), as enacted by section 57 of these Regulations, come into force on January 1, 2023.

SCHEDULE 1

(Subsection 2(1) and 33(2))

Information for Extension of Period for Repair of Equipment Component

- 1 The name and civic address of the operator.

- 2 The name, job title, civic and postal addresses, telephone number and email address of the operator’s authorized official.

- 3 The name, job title, civic and postal addresses, telephone number and email address of a contact person, if different from the authorized official.

- 4 The name of the facility and the federal and provincial identification numbers for the facility, if any, and its civic address or, if the civic address is not available,

- (a) its latitude and longitude to the third decimal place;

- (b) its location expressed to the nearest unit of the National Topographic System produced by the Department of Natural Resources; or

- (c) the legal subdivision within which the facility is located, if it is located in Manitoba, Saskatchewan or Alberta.

- 5 The date on which the next planned shutdown of the facility is to end.

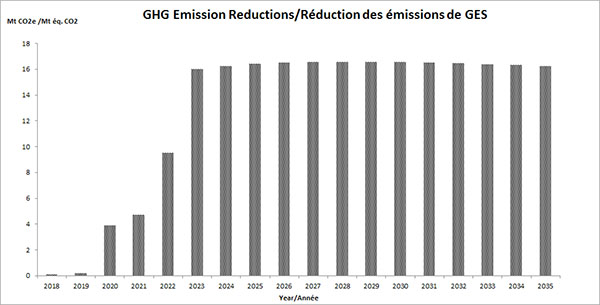

- 6 The following information in respect of the equipment component for which the extension to the period by which it must be repaired is applied for: